Properties of zinc-base wear-resistant alloy

As a superior material for wearing parts,the zinc-base wear-resistant alloy performs the character of abrasion and wear resistance very well. Compare to the copper alloy,it greatly helps to prolong the duration of mechanical transmission parts, machining precision, extend maintenance period of equipments and improve the production efficiency. With a high lubricant adaptability and conductivity, it works well on heat dissipation, temperature controll and anti-seizing effects.

Advantages of zinc-base wear-resistant alloy

Low speciflc gravity and economic. High abrasion and wear resistance,durable. Effects well on heat dissipation and anti-seizing.

Application of zinc-base wear-resistant alloy bearings

Zinc-base wear-resistant alloy bearing is applied to all kinds of construction machinery to replace the tradition copper alloy made products, such as bush, shell, sliding block, sliding plate, gear, worm-gearing and etc.

In recent years, it is gradually used in metal forming machine, water pump, injection machine, crane and other equipments, and achieved successfully in steel rolling, oil, mine and valve industries.

| Technical Reference | zqsn6-6-3 | zqsn10-1 | zqa19-4 | Zinc-base alloy TYXJ6 |

|---|---|---|---|---|

| Tensile Strength n/mm2 | 180~220 | 220~250 | 400~500 | 400~460 |

| Elongation % | 6 | 3~5 | 10 | 1.5~4.0 |

| Hardness HB | 65 | 80 | 110 | 95 |

| Coefficient of Friction (Dry) | 0.16 | 0.14 | 0.16 | 0.12 |

| Coefficient of Friction (Oil) | 0.16 | 0.14 | 0.16 | 0.10 |

| Speciflc g/mm3 | 8.82 | 8.98 | 7.7 | 6.0 |

| Linear Expansion 10-a | 17.1 | 18.5 | 18.1 | 25 |

| Heat Conductivity c.s.c | 0.22 | 0.12 | 0.14 | 0.24 |

| Compression Set 400n/mm2 | <0.05 | <0.05 | <0.05 | <0.05 |

| Max. Temp. | 300℃ | 300℃ | 300℃ | 150℃ |

| PV Limit | 0.5n/mm2.m/s | 0.5n/mm2.m/s | 0.5n/mm2.m/s | 0.5n/mm2.m/s |

| Max. Dynamic Load mm2 | 30n/mm2 | 40n/mm2 | 50n/mm2 | 50n/mm2 |

| At the same time, according to TYB can provide customers with a variety of alloy material | ||||

Metallurgical Structure of Zinc-base Wear-resistant Alloy

The zinc-base wear-resistant Alloy, which is higher insentive and tough, is widely used to manufacture sheet-metal parts, bush, sliding block, sliding plate, gear, worm-gearing and etc.

| Size | Hardness | Sliding Velocity | Unit Pressure | Movement | Shaft | Testing Time | Terms |

|---|---|---|---|---|---|---|---|

| φ40×φ50×l30 | ≥98hb | v=1.0m/min | p=24.5n/mm2 | Rotation | 45#hrc40-45ra0.8 | 50小时 | Dry Friction |

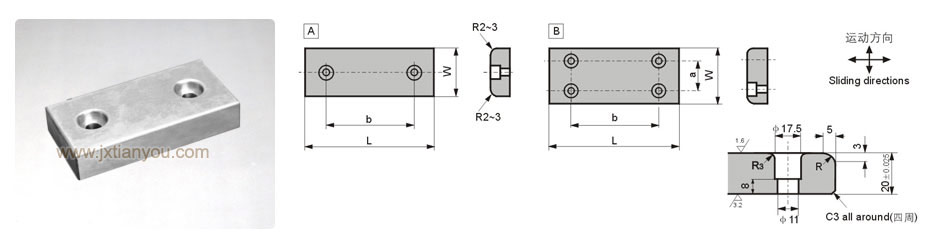

| Unit:mm | |||||

| standard no. | w | l | a | b | sketch |

|---|---|---|---|---|---|

| TYxjp 28x75 | 28 | 75 | 45 | a | |

| TYxjp 28x100 | 100 | 50 | |||

| TYxjp 28x150 | 150 | 100 | |||

| TYxjp 38x75 | 38 | 75 | 45 | ||

| TYxjp 38x100 | 100 | 50 | |||

| TYxjp 38x150 | 150 | 100 | |||

| TYxjp 48x75 | 48 | 75 | 45 | ||

| TYxjp 48x100 | 100 | 50 | |||

| TYxjp 48x125 | 125 | 75 | |||

| TYxjp 48x150 | 150 | 100 | |||

| TYxjp 48x200 | 200 | 150 | |||

| TYxjp 58x75 | 58 | 75 | 45 | ||

| TYxjp 58x100 | 100 | 50 | |||

| TYxjp 58x150 | 150 | 100 | |||

| TYxjp 75x75 | 75 | 75 | 25 | ||

| TYxjp 75x100 | 100 | 50 | |||

| TYxjp 75x125 | 125 | 75 | |||

| TYxjp 75x150 | 150 | 100 | |||

| TYxjp 75x200 | 200 | 150 | |||

| TYxjp 100x100 | 100 | 100 | 50 | 50 | b |

| TYxjp 100x125 | 125 | 75 | |||

| TYxjp 100x150 | 150 | 100 | |||

| TYxjp 100x200 | 200 | 150 | |||

| TYxjp 100x250 | 250 | 200 | |||

| TYxjp 100x300 | 300 | 200 | |||

| TYxjp 125x125 | 125 | 125 | 50 | 75 | |

| TYxjp 125x150 | 150 | 100 | |||

| TYxjp 125x200 | 200 | 150 | |||

| TYxjp 125x250 | 250 | 200 | |||

| TYxjp 125x300 | 300 | 200 | |||

| TYxjp 125x350 | 350 | 200 | |||

| TYxjp 150x350 | 150 | 150 | 100 | 100 | |

| TYxjp 150x200 | 200 | 150 | |||

| TYxjp 150x250 | 250 | 200 | |||